Legacy Portfolio

Risk

Legacy parts have unpredictable demand, which can be disruptive or costly for OEMs to manage. Poor availability and long lead times create opportunities for non-genuine suppliers to erode OEM revenue, reputation, and control.

Our Solution

Enhance part availability and service levels through on-demand manufacturing.

Digital inventory platform

Global supplier network

Why OEMs are choosing Pelagus for on-demand manufacturing for legacy parts

- Revenue protection. Safeguard the aftermarket and prevent sales erosion from non‑genuine suppliers

- Enhanced service level. Ensure consistent part availability with predictable, dependable delivery

- Lower inventory costs. Replace physical stock with a digital inventory to reduce carrying costs

- OEM-grade quality. Every part is produced to OEM specifications and requirements

- IP security. Protect technical data with secure processes across every manufacturing step

- Faster Lead-times. Use advanced manufacturing technologies to shorten production cycles

- Localized manufacturing. Produce parts closer to the point of need through our global partner network

Why asset and vessel managers prefer Pelagus on-demand for their ageing fleets

- Minimized downtime. Ensure critical parts are available faster, reducing unplanned and costly delays

- OEM‑certified quality. Access genuine OEM‑level parts that perform reliably, keeping warranties and SLAs intact

- Direct OEM access. Connect seamlessly with OEMs and their verified on‑demand parts through a single platform

- Digital supply chain enablement. Use on-demand manufacturing to complement predictive maintenance and enhance responsiveness

- Localized manufacturing. Source parts closer to the point of need via our global partner network, reducing lead times and logistics risks.

- Lower carbon footprint. Eliminate unnecessary supply steps to cut transport emissions and support ESG goals.

Getting started

OEMs / Genuine makers

1. Full Portfolio Vision

Our aim is to digitize your entire legacy portfolio and make it available on‑demand, creating a comprehensive aftermarket solution for your customers.

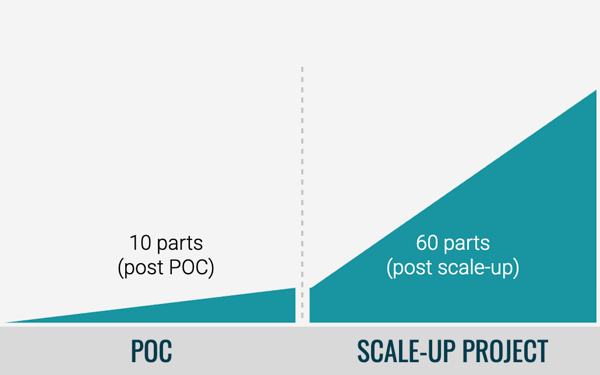

2. Proof of Concept (POC)

We begin with a POC program, selecting key portfolio parts together with interested customers. This provides a low‑risk way to demonstrate the value of on‑demand spare parts in real use cases.

3. Scale‑Up & Expansion

Building on proven success, we work with you to systematically expand across your legacy portfolio. This achieves a critical mass of digital inventory that enhances service levels, protects revenue, and supports long‑term growth.

Asset and vessel managers

1. Asset & Parts Assessment

We start by mapping your ageing assets and identifying which OEMs and legacy parts are most suitable for on‑demand manufacturing. This ensures critical components are available when needed.

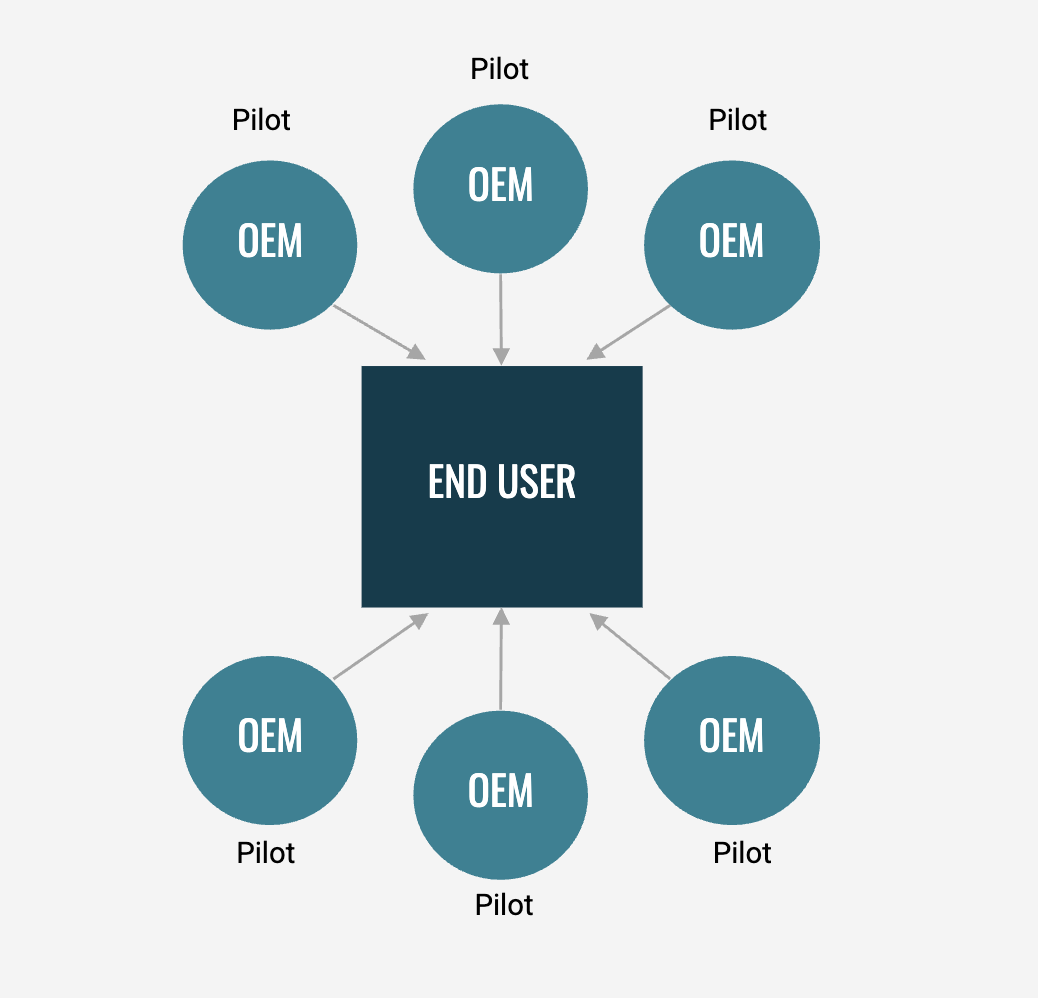

2. Proof of Concept (POC)

Together with select OEM partners, we run a POC program on identified parts. This demonstrates reduced lead times, reliable quality, and the operational benefits of digitised spare part supply.

3. Scaled Adoption

After proving the value, we expand your digital inventory across more OEMs and parts. This gives you broader coverage, greater agility, and sustained uptime for your fleet.

Asset and vessel managers

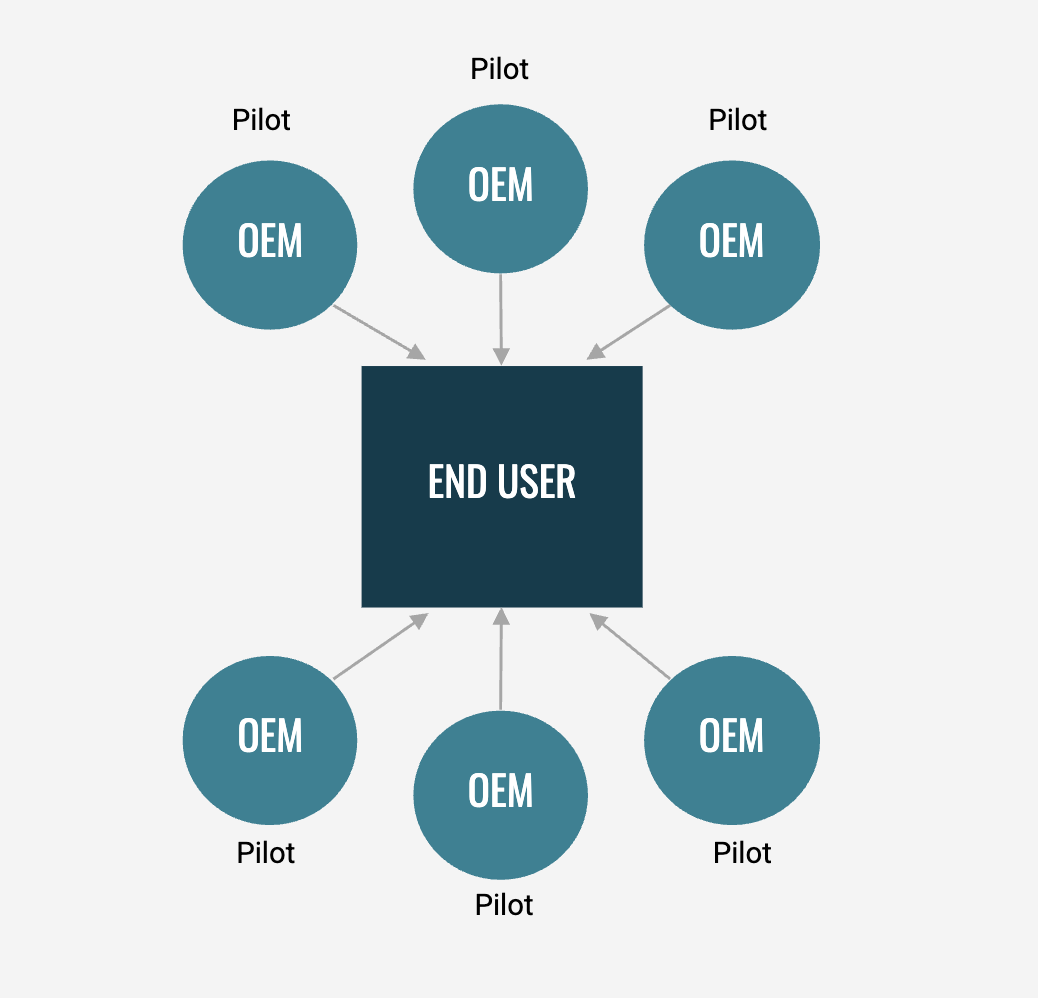

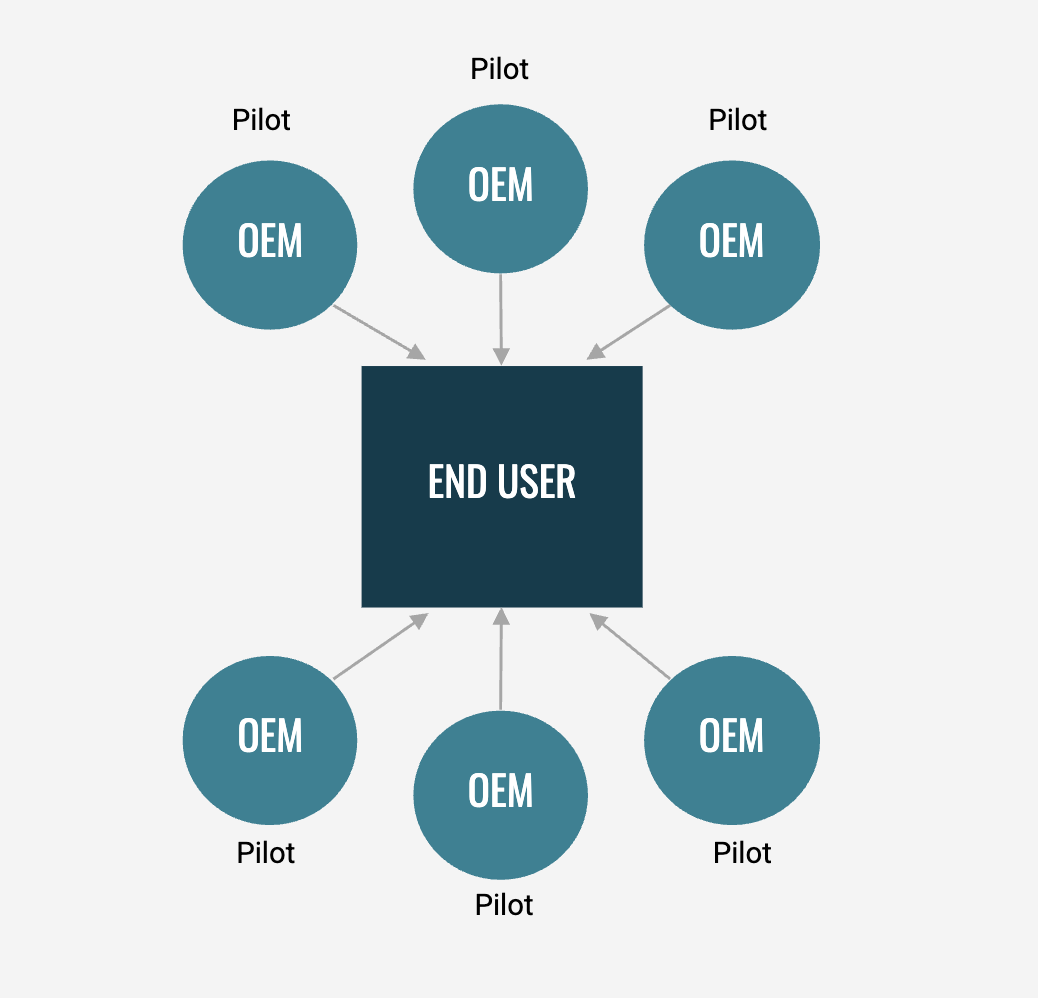

1. Asset & Parts Assessment

We start by mapping your ageing assets and identifying which OEMs and legacy parts are most suitable for on‑demand manufacturing. This ensures critical components are available when needed.

2. Proof of Concept (POC)

Together with select OEM partners, we run a POC program on identified parts. This demonstrates reduced lead times, reliable quality, and the operational benefits of digitised spare part supply.

3. Scaled Adoption

After proving the value, we expand your digital inventory across more OEMs and parts. This gives you broader coverage, greater agility, and sustained uptime for your fleet.

Our 4-Week Promise

OEM‑Certified Quality, Delivered in Weeks

Through our digital inventory and global network of suppliers, qualified components cn be produced and dispatched in as little as four weeks. Even when complex testing extends timelines, our approach ensures a faster, more reliable route to delivery.

.png)